We’re on the cusp of a new era in connectivity, but as next-generation wireless 5G networks roll-out across the globe, what’s in it for the manufacturing industry?

While the consumer-facing telecoms companies talk only about the speed of downloads, for manufacturing, the focus turns to ultra-reliable low-latency, density and ubiquitous connectivity. It’s these lesser-known features, beyond the breakneck 5G speed, that will encourage industry to construct private 5G network infrastructure in industrial plants and warehouses.

The sector is a production line for buzzwords; everything from the Industrial Internet of Things (IIoT) to Industry 4.0 are common, with ‘smart factories’ and ‘edge computing’ not far behind.

From high-precision assembly lines and augmented reality overlays, to cloud robotics and cable-free factories, here are 12 ways 5G could transform manufacturing.

1. AR headsets & glasses

Although it's an overstated part of 5G, there is no getting away from the fact that the ability to download data much, much faster will be a major attraction of 5G to the manufacturing industry. Promising eventual download rates of 20 Gbps and – just as importantly – upload rates of 10Gbps, 5G networks will be up to 100 times faster than 4G networks. The most immediate advantage of this so-called ‘enhanced mobile broadband (eMBB)’ feature will be the ability to share and stream 4K quality videos with ease, which could very quickly morph into virtual reality content and augmented reality overlays. Expect head-worn augmented reality headsets, helmets and glasses for construction, troubleshooting, remote diagnosis, maintenance and inspection to make use of the extra bandwidth. However, first-get 5G networks don’t yet reach anywhere near 5G’s peak data rates.

2. Low latency

5G networks will come close to eliminating the problem of latency. Latency is not to be confused with speed or bandwidth. While the latter is about how much data you can receive in one second, latency describes the delay on the line when sending information from one place to another. Latency is measured in milliseconds (ms), and just to give you some context, most modern 4G networks have a latency of around 50 ms. But with 5G networks using URLLC (Ultra-Reliable and Low Latency Communications) latency can theoretically reduce that to a single millisecond, essentially rendering the issue of latency meaningless. The advantages to manufacturers are many; think high-precision assembly lines where all machines and robots are perfectly in sync in real-time, the mass-adoption of the Internet of Things (IoT), and even humans controlling machines via touch. However, the first generation of 5G networks tend to offer around 10ms latency, so, for now, latency is still an issue. Expect second-gen 5G networks to be mostly about reducing latency.

3. Ubiquitous connectivity

5G is about capacity and density as much as it is about speed. The specification for 5G networks allows up to one million devices per square kilometre, which is a massive attraction for industry as it theoretically breathes life into machine-to-machine (M2M) communications, and the Industrial IoT (IIoT) as a whole. In a manufacturing context, those devices are everything from sensors, machines and robots to wearables, autonomous vehicles and VR headsets. However, 5G networks don't yet reach this maximum specification, so it could take a few years before the capacity aspect of 5G networks becomes attractive to manufacturers.

4. Intelligent factories and Industry 4.0

5G in a manufacturing context is not about making use of publicly available 5G connections as used by consumers. No, 5G for industry is about constructing custom-made, private 5G networks that essentially bring alive the idea of an Intelligent or ‘smart’ factory. Also known as Industry 4.0, this is about abandoning the old ways to embrace connected systems to encourage more streamlined automation in a closed environment. With the Internet of Things (IoT) in full deployment and connected sensors on every machine, the aim is to predict problems, see problems emerge in real-time, and reduce production downtime. The secret sauce will be AI-capable analytics software to crunch real-time data on every machine and piece of equipment.

5. AI and edge computing

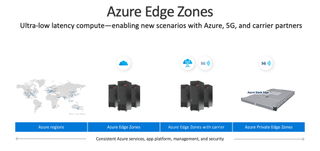

Despite the consumer focus being on smartphones, it’s fibre optic cables that will be the backbone of next-gen 5G networks. And it’s fixed-line wireless routers in industrial plants and command centres that will bring super-fast wireless connections to manufacturers. However, for truly latency-free requirements, and merely to save money on the sending (and storing) all of its data to the cloud and back, factories will need ‘edge’ computing services, such as Microsoft's new Azure Edge Zones. Also known as ‘fog’ computing, this is the process of computing data and enabling analytics close to its source rather than in the cloud. Cue mini data centres in manufacturing plants, which also adds a layer of data privacy and security.

6. Cable-free ‘cloud-first’ factories

Manufacturers currently rely on fixed-line networks, with WiFi a rarity. However, the installation of 5G fixed-line wireless routers in industrial plants will render cables and clutter a thing of the past for manufacturers. By cutting cables, factories could become much more flexible, allowing production lines to be moved and redesigned much more quickly. 5G will also mean machines and robots – as well as sensors, and even untethered tools such as high-precision ‘smart’ screwdrivers – can be connected wirelessly to both each other, and to the cloud.

7. Industrial Internet of Things (IIoT)

Also known as machine-to-machine (M2M) connectivity, this is the trend that’s seeing the manufacturing sector getting connected. With cut-throat competition and an unpredictable global market, industry is having to streamline and become autonomous. For now, it’s based on 4G, but the sheer volume of data that can be swapped and streamed, together with that ultra-low latency, means the IIoT will ultimately become a 5G-powered trend.

8. Tactile internet and remote touch

5G is often described as being able to create the ‘zero touch factory’. However, what about when human input is needed? The so-called ‘tactile internet’ is all about instant, interactive communications using remote haptic (sense of touch) technologies, but it’s very often described with the example of a doctor performing an operation on someone from somewhere else in the world. That’s not what it’s about. Instead, it’s about taking advantage of 5G’s ultra-low latency to allow a human to perform a task using robotically-assisted devices, but in the same room; think powerful remote control from a console for maintenance and repair, including in remote areas and for high risk and precision tasks, such as mining.

9. Cloud robotics

Get ready for real-time robotics. Production robotics are already firmly ensconced in the manufacturing industry, but 5G will do much more than just make them wireless. Cue 5G-enabled 'co-operative cloud robots', which use 5G's lightning-fast speeds and ultra-low latency to work in sync with each other. Take two robots on a production line linked to the same ‘edge cloud’ wirelessly over 5G; they can exchange video streams quickly, but also stay in sync with each other by communicating their exact positions to each other. Ultimately, 5G means that one robot can throw a ball and the other one can catch it. More practically, they can keep equipment and products perfectly balanced while they work on them simultaneously. The tech could also be used to keep drones balanced as they buzz around factories.

10. Autonomous vehicles

Out in the wider world, self-driving cars will probably never come to pass in their present form. There are just too many variables for artificial intelligence to accurately predict. However, that's not the case in the closed environment of a large industrial plant. Just as vacuum cleaners can learn the layout of the house and autonomously clean them while you're out at work, so too could an army of vehicles move around industrial plants and warehouses fairly easily. The enabling technical, of course, is 5G, which would allow the vehicles to communicate their position to each other in real time, thus avoiding crashes.

Once you look beyond public roads, and consider industrial 5G use cases, autonomous vehicles are already being deployed in factories around the world, with KT – Korea’s largest telecommunications service provider – being the latest company to implement self-driving machines.

KT has introduced 5G self-driving carts at its logistics center, enabling a nearly 50 percent reduction in employees’ travel range for loading and transporting inventory. The new system is the first use of next-generation smart logistics vehicles in the Korean communications industry, with two types of 5G self-driving carts – “NarGo” and “TarGo” – being employed in collaboration with Twinny, a company specializing in indoor autonomous robots and online platforms.

And we have already seen 5G robots helping the Chinese authorities fight coronavirus in public spaces.

11. Time sensitive networking (TSN)

Time Sensitive Networking (TSN) is a family of the IEEE 802.1 standard that enables time synchronization and data delivery within an IoT setting, and it includes strict latency bounds, which are vital if technology is going to work in an industrial setting, with multiple connected devices.

To date, TSN networks have been implemented using Ethernet technology, but with the increasing rollout of 5G technology, wireless TSN is becoming a reality for the first time. And according to a new ‘Time-Sensitive Networking Market’ report from Global Market Insights, the TSN market surpassed $200m in 2019 and is expected to have a compound annual growth rate (CAGR) of more than 30% between 2020 and 2026, taking the market size to more than $1bn by the end of that period.

With the potential to enable wireless connectivity for a variety of industrial applications, 5G use cases using TSN will be a boon for manufacturers of end-devices and systems across IIoT, enabling them to easily reconfigure industrial automation, control systems, factory automation, and other elements of Industry 4.0. And we can expect wireless TSN and 5G to completely transform the future of wireless networks with high reliability, resiliency, and security.

“Industry players are emphasizing on developing TSN components for next generation 5G network,” the report said. “For instance, in November 2019, Infinera introduced its X-haul-optimized TSN optical switch for 5G network and deep fiber applications. This new solution helps network operators to deploy 5G and deep fiber applications cost-effectively.”

The increasing demand for real-time networking across different industry sectors, such as manufacturing, automotive, transportation, energy & utility, aerospace, and oil & gas, is also helping the market grow.

“The rising adoption of autonomous vehicles is enabling leading market players to develop innovative TSN components for automotive applications,” according to the report. “For instance, in January 2020, NXP Semiconductors introduced a safe automotive ethernet switch, e NXP SJA1110 for TSN. This new product launch helped the company to help automotive manufacturers to deliver high-speed networks required for connected vehicles. The NXP SJA1110 helps in providing a high level of performance, security, and safety for automotive applications.”

With the potential to enable wireless connectivity for a variety of industrial applications, 5G use cases will be a boon for manufacturers of end-devices and systems across IIoT, enabling them to easily reconfigure industrial automation, control systems, factory automation, and other elements of Industry 4.0. We can expect wireless TSN and 5G to completely transform the future of wireless networks with high reliability, resiliency, and security.

12. Video monitoring and detection

“This makes the security industry an attractive channel to market for CSPs, who could benefit from establishing partnerships with leading security providers.”

Nokia report.

According to a Nokia report, 5G-enabled video was the number one use case among enterprises, with 83% finding it appealing. This is driven by the fact that 75% of the organizations surveyed are already using some form of video monitoring today – whether it’s monitoring premises, people coming and going, or operations.

“While SMBs may invest in just one 5G video camera, larger businesses are likely to purchase 5G-enabled video monitoring and detection technology as part of a wider suite of security services,” the report said. “This makes the security industry an attractive channel to market for CSPs, who could benefit from establishing partnerships with leading security providers.”

- Discover the best 5G networks in the UK and US

- Get your hands on the hottest 5G phones

- Millimeter wave: the secret sauce behind 5G

- The complete guide to 5G security

- We reveal the latest 5G use cases

- Discover the truth behind 5G dangers

- 5G towers: everything you need to know